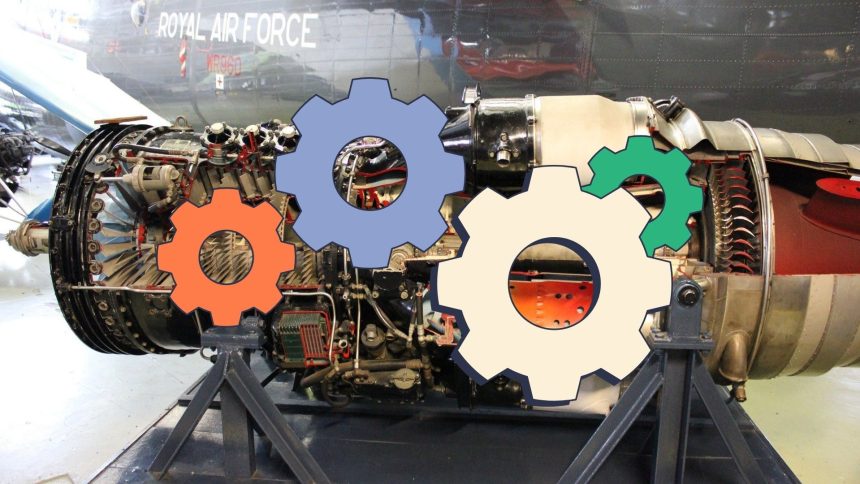

In the realm of aerospace engineering, where precision and performance are paramount, one material has emerged as a game-changer, propelling jet engines into new dimensions of efficiency and power. As aircraft soar across the skies, a silent revolution is taking place beneath the hood—an evolution fueled by cutting-edge materials that push the boundaries of what is possible. From the demands of supersonic speeds to the challenges of extreme temperatures, engineers have turned to a mighty material that not only enhances thrust but also optimizes fuel consumption and reduces emissions.

In this exploration, we delve into the science and innovation behind this extraordinary substance, uncovering how it supercharges jet engines and reshapes the future of air travel. Join us as we take flight into the world of aerospace materials that hold the key to unlocking unparalleled performance in the skies.

The Transformative Power of Advanced Alloys in Jet Engine Design

Often unnoticed but essential, advanced alloys have become the unsung heroes of modern aviation. These robust materials, designed to withstand extremes of temperature, pressure, and stress, are revolutionizing jet engine design and functionality. Far from generic metals, these super-materials are complex blends of elements, each fine-tuned to offer unique properties and benefits.

- Nickel-based superalloys: Offering exceptional heat resistance, these alloys help in maintaining the structural integrity of jet engines even in the face of extreme temperatures.

- Titanium aluminides: Lighter and more heat resistant than conventional titanium alloys, titanium aluminides provide better fuel efficiency.

- Aluminum-lithium alloys: Known for their lightweight and high-strength features, these alloys reduce engine weight and boost performance.

Let’s take a closer look at these elements through the lens of an HTML table before plunging deeper into their contributions:

| Material | Heat Resistance | Weight | Strength |

|---|---|---|---|

| Nickel-Based Superalloy | Excellent | High | Excellent |

| Titanium Aluminides | Very good | Medium | Good |

| Aluminum-Lithium Alloys | Good | Low | High |

The enhanced properties of these advanced alloys not only aid in the creation of powerful and efficient jet engines but also lead to sustainable aerospace development. With the pressure to reduce emissions, improve fuel efficiency, and enhance durability, advanced alloys pave the way forward. The future of aviation indeed rests heavily on these mighty materials, highlighting .

Harnessing the Heat: How Superalloys Enhance Performance and Efficiency

When considering materials that can withstand extreme temperatures and pressures, one might first think of diamonds or perhaps some form of advanced ceramic. However, in reality, a class of mighty materials known as superalloys are the heroes behind some of modern technology’s most staggering achievements. These superalloys are heavily relied upon in industries where performance under harsh conditions is paramount, such as in jet engines or power plants. With their ability to maintain structural integrity under intense heat and stress, superalloys enable equipment to operate at higher temperatures that increase efficiency and performance.

So, what’s the secret behind these performance-enhancing materials? Superalloys derive their extraordinary properties from a balanced mix of elements. Key among these are Nickel, Cobalt and Iron, which form a robust matrix to which other elements are added to refine and enhance the alloy’s performance. Today, we will venture into a typical composition of primary elements:

| Element | Function |

|---|---|

| Nickel | Provides strength and corrosion resistance |

| Cobalt | Increases temperature resistance |

| Iron | Enhances magnetic properties |

| Chromium | Improves oxidation resistance |

| Titanium & Aluminium | Stabilizes the superalloy at high temperatures |

| Tungsten & Molybdenum | Boost hardenability and durability |

Alongside these, a cocktail of other elements are often added to further tweak the alloy’s capability. Elements such as ruthenium, rhenium, and hafnium are commonly included to improve temperature resilience and life span of the superalloys. In this way, superalloys truly live up to their name, providing super-powered solutions for the toughest engineering challenges.

From Innovation to Implementation: Best Practices in Material Selection

When it comes to propelling the awe-inspiring, jaw-dropping power of modern jet engines, it is the material chosen that plays a crucial role. Referred to as superalloys, these mighty materials are specifically designed to withstand the extreme heat and stress generated within the jet engines. The material, usually a complex combination of nickel, cobalt, or iron, is crafted meticulously with impressive mechanical strength and exceptional resistance to thermal fatigue. To further enhance these qualities, researchers often use precipitation hardening, a heat treatment technique that makes the alloys even more resilient.

The decision-making process for material selection involves a detailed evaluation based on performance, safety, and cost efficiency. Below are some best practices:

- Thorough Testing: Invest in comprehensive testing to ensure the material can withstand infernal temperatures, extreme pressure, and harsh chemical environments.

- Scalability: Consider the scalability of production, which impacts the overall cost efficiency and time frame within which the engine will be built and deployed.

- Sustainability: Explore the environmental impact of the material’s extraction, manufacture, use, and disposal, with an eye on selecting materials that promote sustainability.

Precise material selection in jet engines not only maximizes performance and reliability but also significantly extends the engine’s lifetime, saving millions in operational costs. For example, let’s look at the two commonly used superalloys:

| Material | Temperature Resistance (in °C) | Notable Quality |

|---|---|---|

| Nickel-Based Superalloy | 980 | Excellent resistance to thermal fatigue |

| Cobalt-Based Superalloy | 1,100 | High creep resistance |

The right material choice, coupled with technological advancement, can truly supercharge a jet engine, taking us boldly into the future of aviation.

Future Frontiers: Emerging Technologies in Jet Engine Materials

In the acceleration of technological advancement where jet engines are pivotal, state-of-the-art materials promise groundbreaking improvements in performance and efficiency. Foremost among these is titanium aluminide (TiAl), a high-performance alloy that is fundamentally altering the future of jet engine technology. TiAl is a robust yet lightweight substance that can withstand tremendous heat while resisting corrosion, thus rendering it ideal for jet engine applications.

As engine components continue to become smaller and more streamlined, the demand for advanced, high-performance materials is accelerating. Some of the most significant benefits of titanium aluminide include:

- TiAl can withstand temperatures up to 800°C, far beyond what many traditional materials can handle.

- This alloy exhibits excellent thermal conductivity, making it highly efficient in heat transfer.

- Due to its lightweight nature, TiAl plays a vital role in reducing the total weight of the engine, thereby increasing fuel efficiency.

- Its resistance to corrosion ensures durability and longevity of engine components.

| Material | Max Temperature | Thermal Conductivity | Corrosion Resistance |

|---|---|---|---|

| Titanium Aluminide (TiAl) | 800°C | High | High |

| Traditional Material | Variable | Moderate | Moderate |

These improvements, driven by the adoption of pioneering materials such as TiAl, promise thrilling levels of efficiency and power for jet engine technology. As we venture into the future, industry experts anticipate that further research and development will lead to the discovery of even more advanced materials, with even greater potential capabilities for jet engine performance.

To Wrap It Up

As we soar to ever greater heights in aviation technology, one material stands out as the unsung hero behind the power and performance of jet engines: advanced ceramics. From the roar of takeoff to the graceful glide through the clouds, these mighty substances not only withstand extreme temperatures but also enhance efficiency and durability in ways that were once thought impossible. As researchers continue to unlock the potential of ceramics, we can anticipate a future of cleaner, more powerful, and more reliable jet propulsion.

The journey of innovation is far from over. Each breakthrough brings us one step closer to revolutionizing air travel, making it faster and more sustainable. As we marvel at the capabilities of modern aviation, let’s not forget the vital role that materials like ceramics play in shaping the skies of tomorrow. With each flight, we are reminded of the profound connection between science and the sublime experience of flight—transforming a mere dream into an extraordinary reality, powered by the might of a remarkable material.